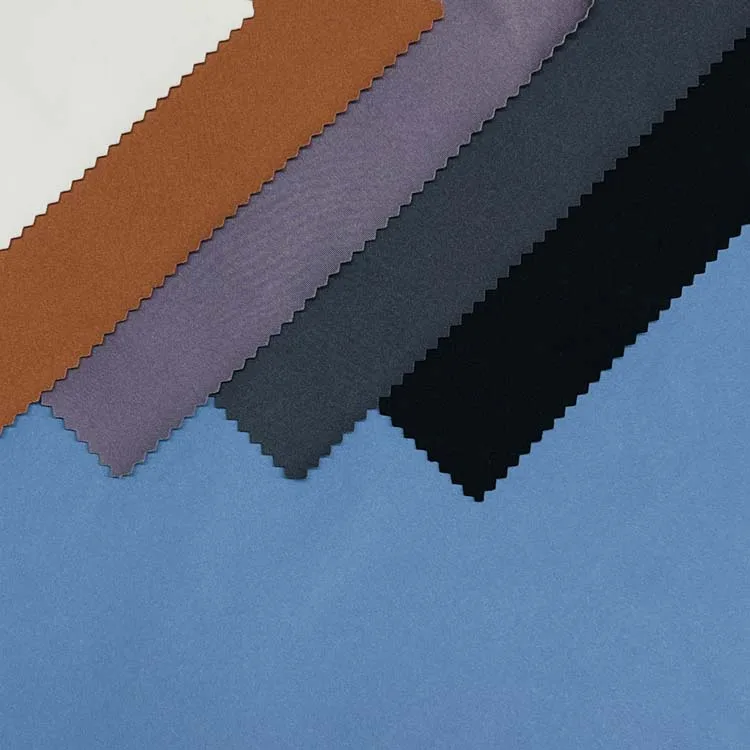

Custom Nylon Spandex Interlock Knit Shapewear Fabric for Active Wear

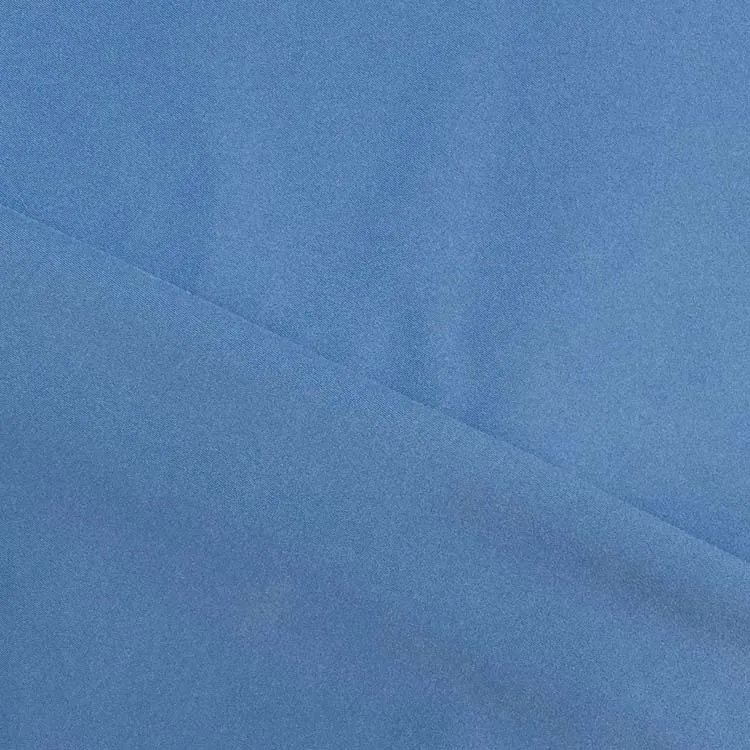

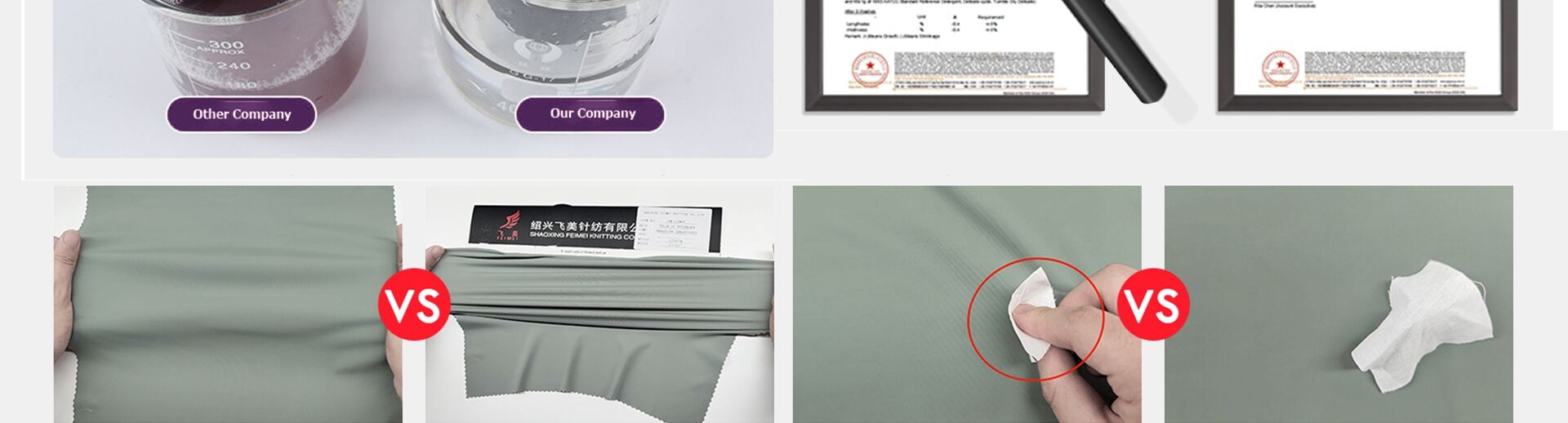

The interlock knit construction ensures a smooth, refined surface on both sides while providing excellent breathability and moisture-wicking properties to keep wearers cool and comfortable during activities. Highly durable and resistant to pilling, this fabric maintains its shape and compression even after repeated wear and washing.

- Overview

- Advantage

- Recommended Products

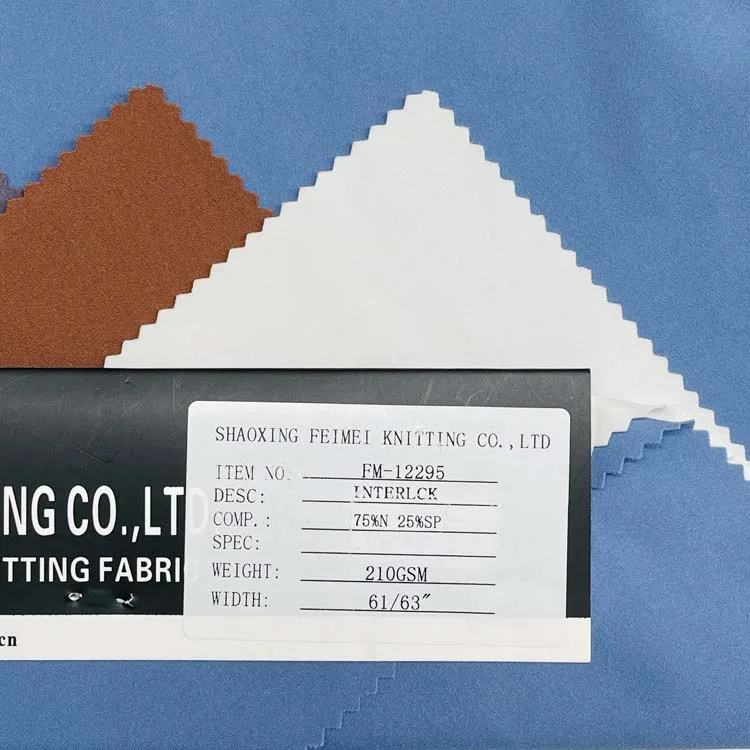

Item Name |

75% Nylon 25%Spandex Interlock Fabric For Yoga Pants Shapewear |

Hanger No. |

FM-12295 |

Composition |

75% Nylon 25% Spandex (According to order)

|

Width |

61/63” |

Weight |

210gsm |

MOQ |

400kgs |

Free Samples |

Free Sample Available |

Usage |

T Shirts, Garment, Pants, Lining, etc |

I. Core Weaving Techniques: The "Skeleton" of Yoga Fabrics

Most yoga fabrics are knitted fabrics, characterized by interlocking loops, which offer excellent elasticity, breathability and softness. Knitting is mainly divided into two categories: weft knitting and warp knitting.

a. Weft Knitting

· Features:

· High elasticity: It has excellent elasticity both horizontally (width) and vertically, especially in the horizontal direction. This is the most essential characteristic for yoga wear.

· Application in yoga wear: The vast majority of yoga wear adopts weft knitting technology because it offers unparalleled fit and freedom. The sweat fabric and double-sided fabric we will discuss below both fall under the category of weft knitting.

b. Warp Knitting

· Features:

· Good stability: The structure is more stable and less prone to curling edges and unraveling.

· Limited elasticity: The elasticity is usually less than that of weft knitted fabrics, especially in the horizontal direction. However, its elasticity can be enhanced by adding elastic fibers such as spandex.

· Smooth and wear-resistant: The surface is usually smoother and more wear-resistant.

· Application in yoga wear: Less common than weft knitting, but often used in areas that require higher support and shaping effects, such as:

· The cups and side wings of high-intensity sports bras.

· The waist of yoga pants or areas that need special reinforcement.

· The surface of some yoga wear that pursues ultimate smoothness and a friction-free touch.

II. Common Categories of Yoga Fabrics: The "Two Kings" of Weft Knitting

a. Cotton jersey fabric

· Features:

· Lightweight and breathable: The structure is relatively simple, the fabric is thin and light, and it has good breathability.

· Soft and skin-friendly: The touch is very comfortable.

· Tendency to curl: The edges will curl up noticeably.

· Application in yoga wear:

· Commonly used for inner linings of yoga wear, basic yoga T-shirts, and loose yoga tops.

· Pure cotton jersey fabric has good sweat absorption, but poor elasticity and quick-drying properties; nowadays, jersey fabric made from a blend of modal, viscose, and spandex is more commonly used, which combines softness, elasticity, and breathability.

b. Double-sided fabric

· Features:

· Stable structure: Thicker and stiffer than sweatshirts, it is less prone to curling and deformation.

· Moderate elasticity: It has excellent resilience and shape retention.

· Rich hand feel: It gives a thick and textured feeling.

· Application in yoga wear:

· This is the most commonly used main fabric for high-end yoga wear, such as Lululemon's classic series (excluding the Align series) and many other brands' main styles.

· It is usually a blend of nylon and spandex, providing a perfect combination: the smoothness, durability and strength of nylon, along with the elasticity of spandex. This fabric offers sufficient support while allowing full range of motion and has a fashionable appearance.

III. Functional Perspective Analysis: The "Soul" of Modern Yoga Fabrics

Apart from the knitting method, the fiber composition and post-finishing process jointly determine the functionality of yoga wear.

a. Core functional dimension

· Elasticity and resilience (freedom of movement):

· Implementation method: Spandex (Lycra) is the core, with a typical blend ratio of 5% to 20%. The weft knitting structure itself also contributes significantly to elasticity.

· Standards for good fabric: High elasticity and good recovery, remaining tight even after prolonged wear.

· Breathability and quick-drying (comfort):

· Implementation method:

· Fibers: Nylon and polyester (PET) have poor moisture absorption, but through the use of profiled fibers (such as cross-shaped or C-shaped), a capillary effect can be created between the fibers to quickly wick away and evaporate sweat, achieving quick-drying. Regenerated cellulose fibers like modal and viscose have good moisture absorption but dry slowly.

· Post-treatment: Moisture-wicking and sweat-absorbing agents can make the fabric hydrophilic, allowing sweat to be removed more quickly.

· Softness and skin-friendliness (touch):

· Implementation method:

· Fibers: Modal and Tencel are renowned for their extreme softness and smoothness. Nylon can also achieve a very soft touch through fine spinning technology (such as Lululemon's Nulu fabric).

· Process: Brushing and grinding treatments can create a layer of short fibers on the inner side of the fabric, providing a "buttery" touch (such as Lululemon's Align series).

· Support and shaping (performance):

· Durability and shape retention (lifespan):

· Implementation method: Nylon has the best abrasion resistance among all fibers, far superior to polyester and cotton. High-quality double-sided fabric has a stable structure and is less prone to pilling and deformation.

b. Examples of Classic Fabric Formulations

· Ultimate Naked Feel Series (such as Lululemon Align):

· Process: Weft knitting, usually sweat fabric or its variants.

· Composition: Nylon + Spandex (but using extra-fine, super-soft nylon filaments).

· Classic Training Series (such as Lululemon Wunder Train):

· Process: Weft knitted double-sided fabric.

· Composition: Nylon + Spandex.

· Post-treatment: Smooth surface, may have a slight fleece feel or quick-dry treatment on the inside.

· Function: Versatile. Good elasticity, excellent support, quick-dry, and durable, suitable for various flow yoga and strength training.

· High Support Series:

· Process: May use warp knitting or high-density double-sided fabric.

· Composition: Polyester + high proportion of Spandex or Nylon + high proportion of Spandex.

· Function: Strong shaping, strong wrapping sensation, suitable for high-intensity interval training or sports with high requirements for chest and waist support.

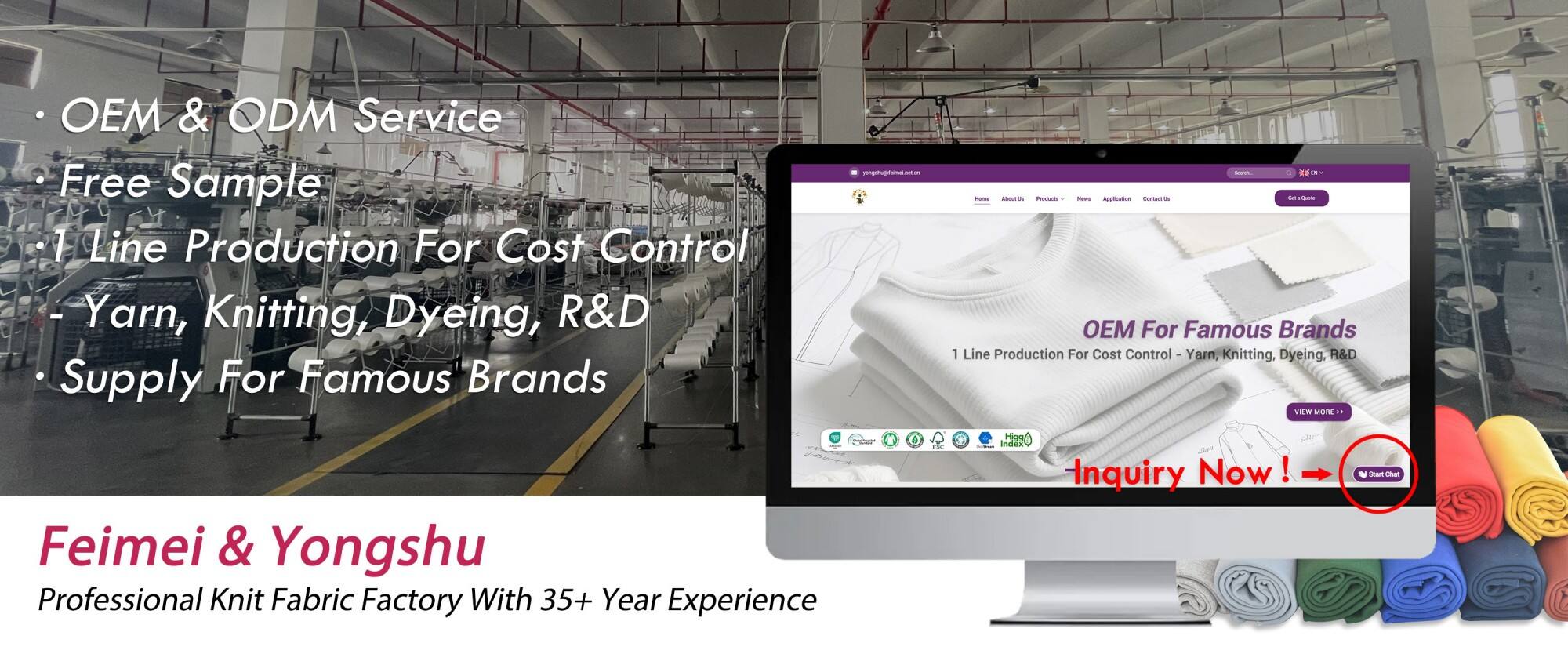

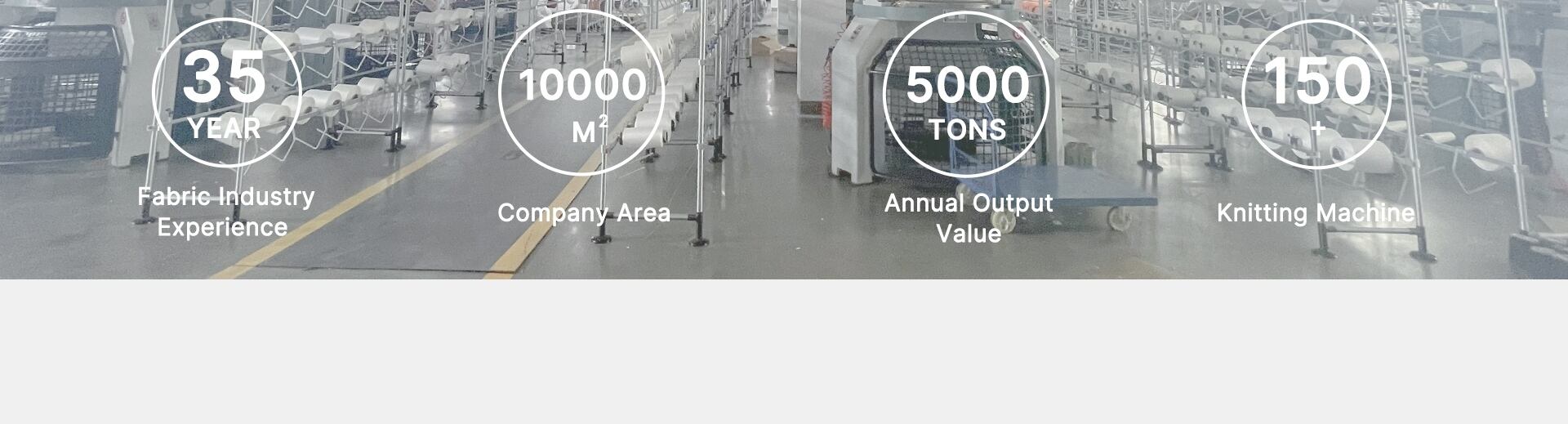

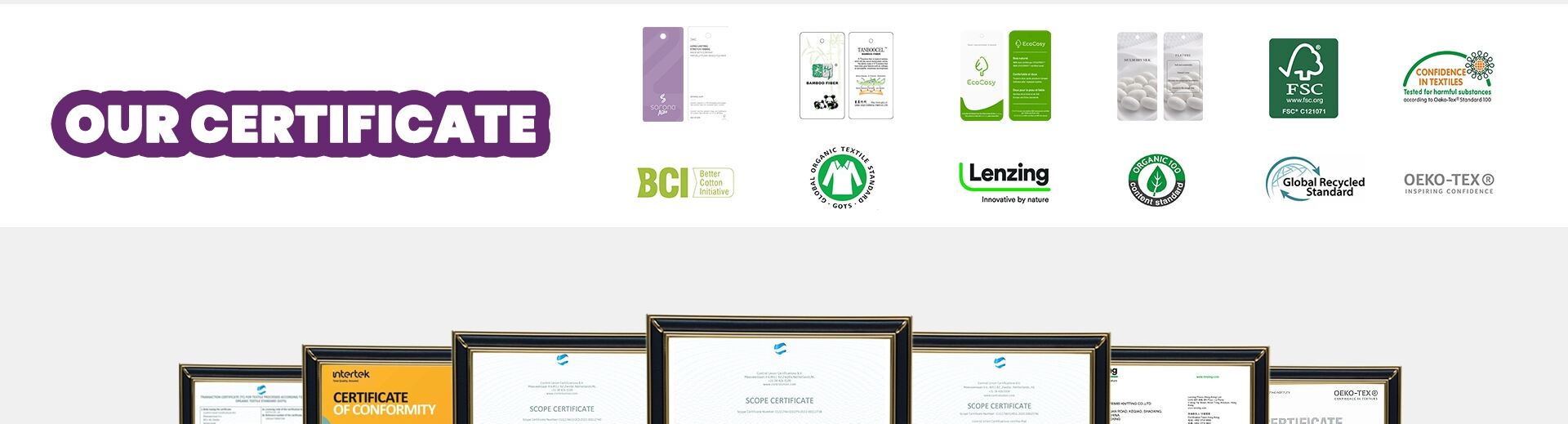

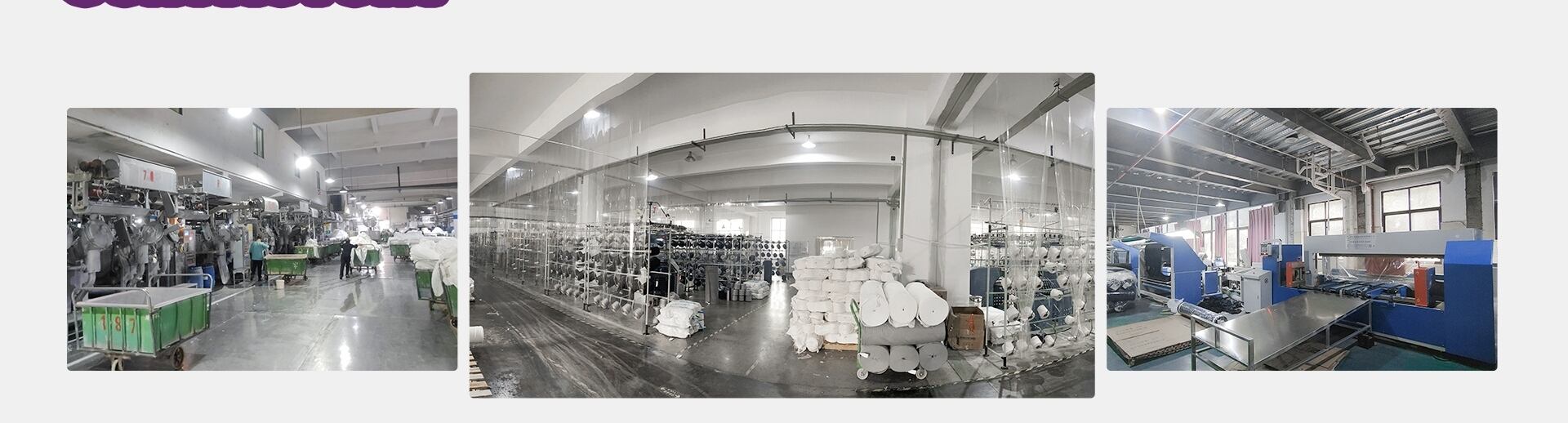

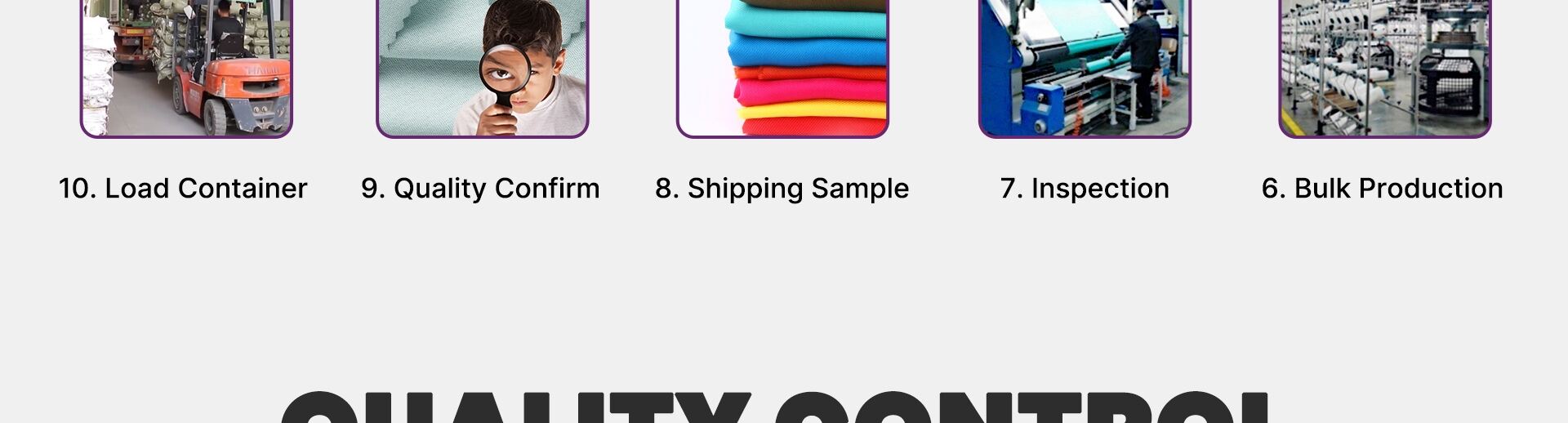

Yongshu / Feimei is a professional knit fabric manufacturer with more than 35 years experience. Certificated by ISO, OEKO, GRS, BCI, GOTS, OCS, FSC, RCS, ZDHC, INDEX, etc. Can do OEM & ODM accordingly.

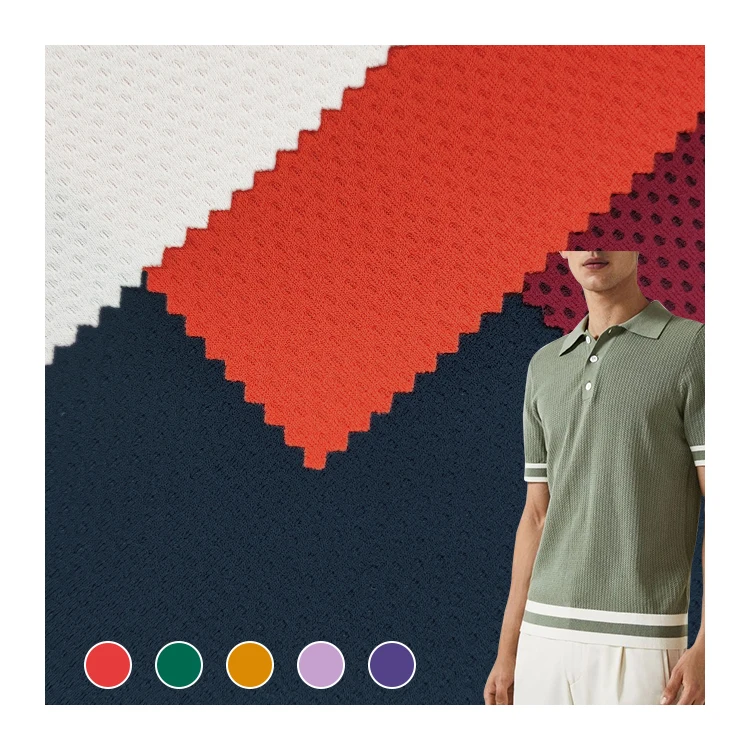

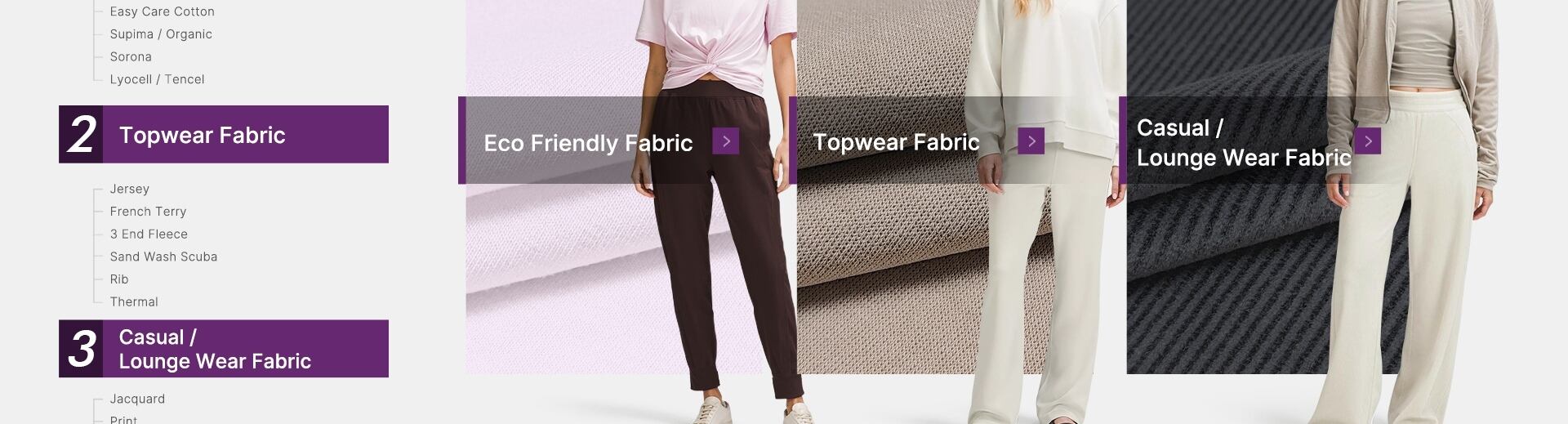

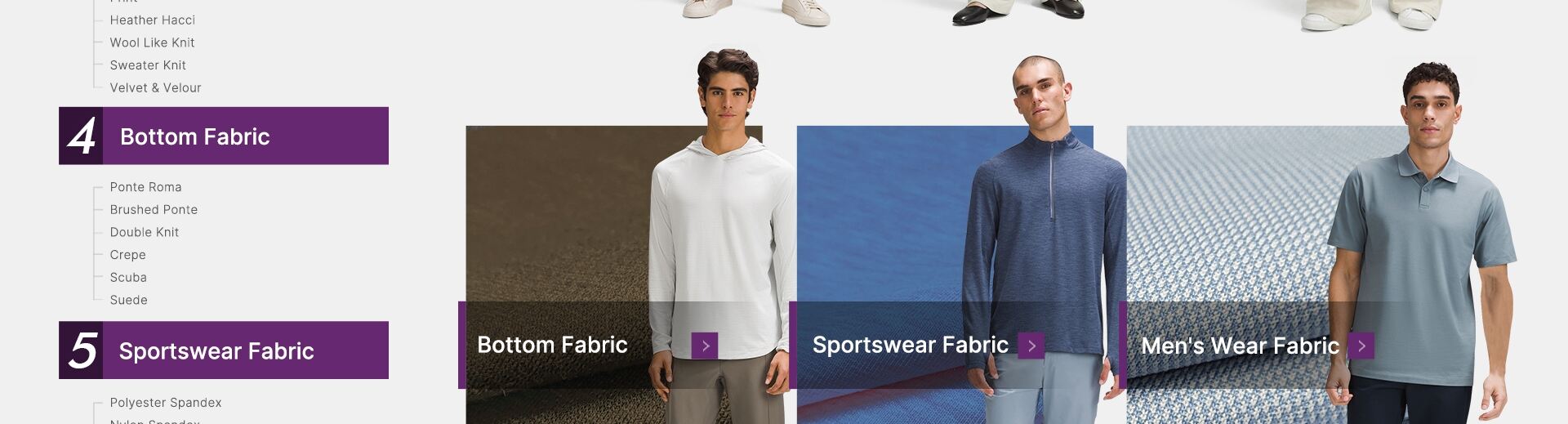

Our main products are various knitted fabrics. Recycle polyester & nylon, also natural material knits like cotton, bamboo, viscose, modal, tencel; Knit suit & pants fabrics by ponte roma, double layer, scuba; Jersey & terry fleece hoodie fabrics for sportswear; Knit print & jacquard fabrics; Rib & hacci fabrics, etc

Hope we can build a long term cooperate relationship !

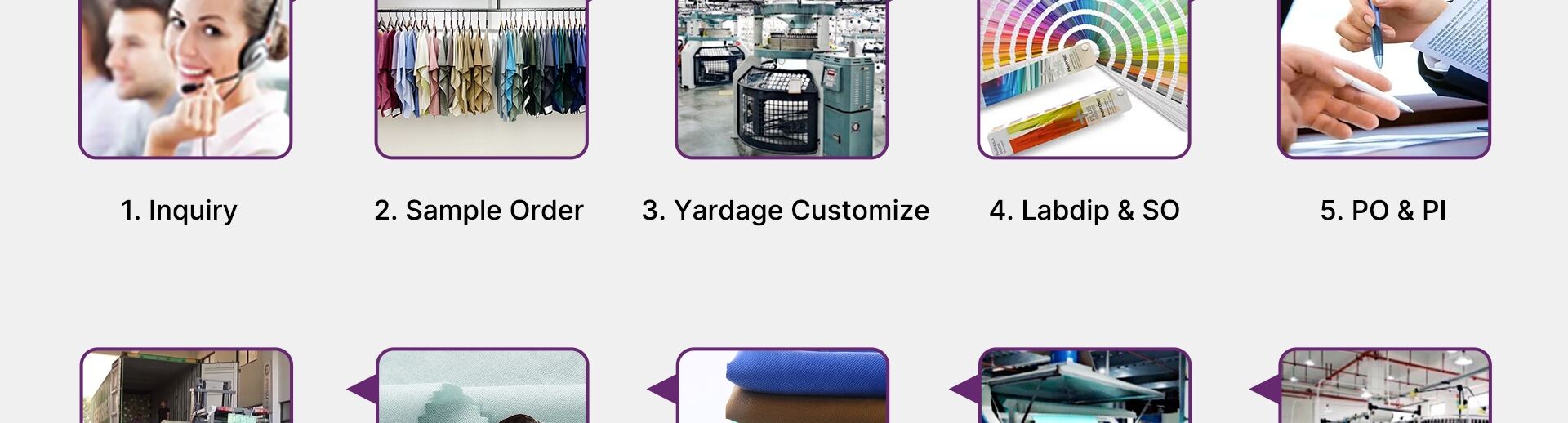

May I know what kind of products are you interested in?