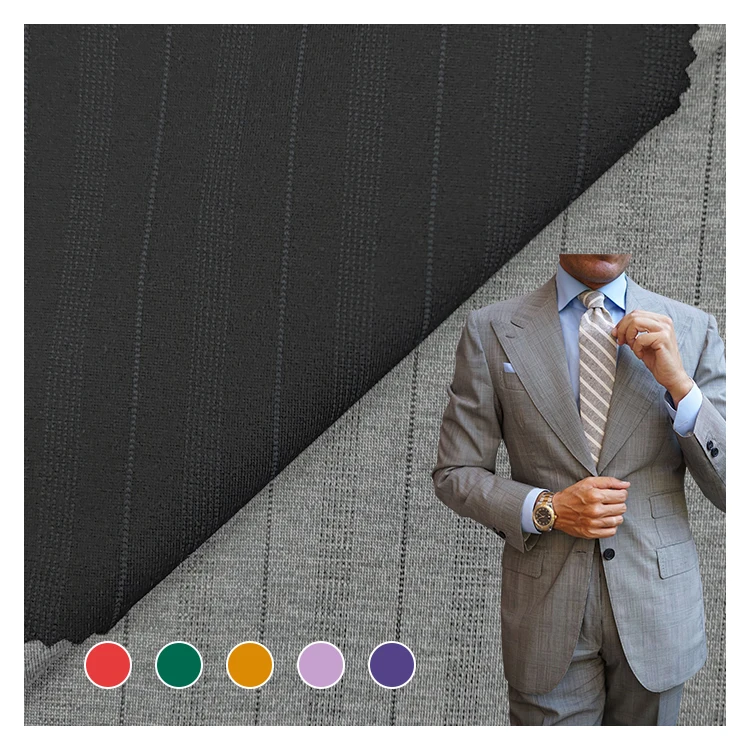

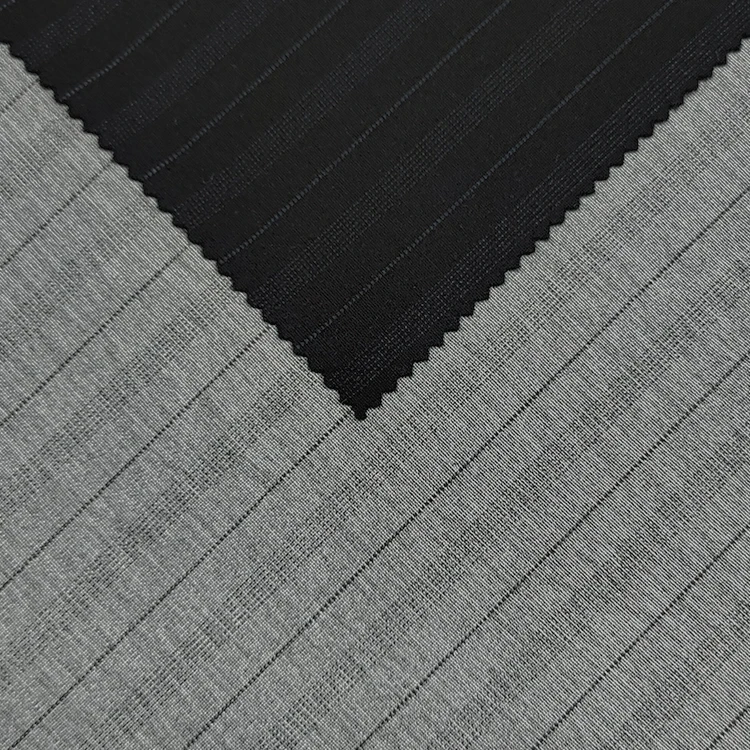

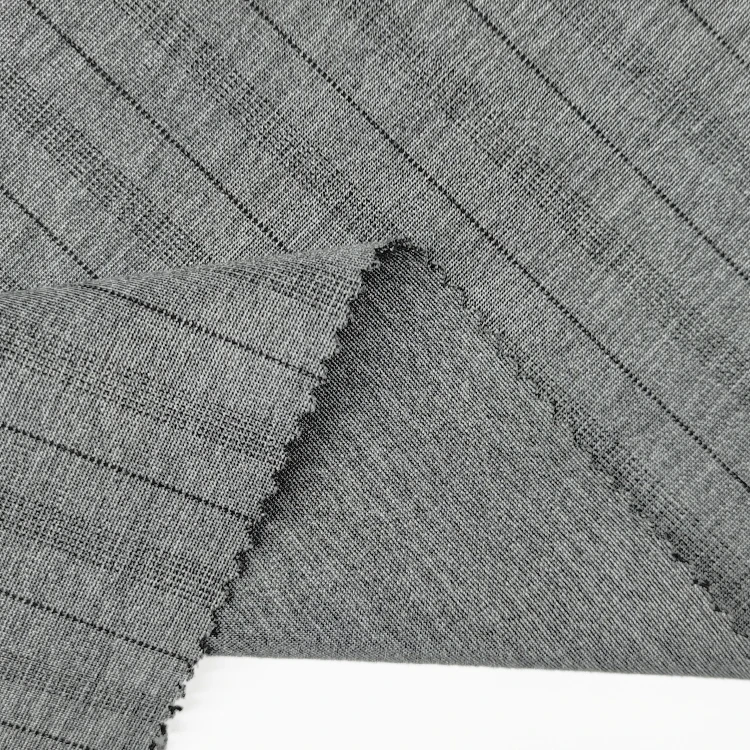

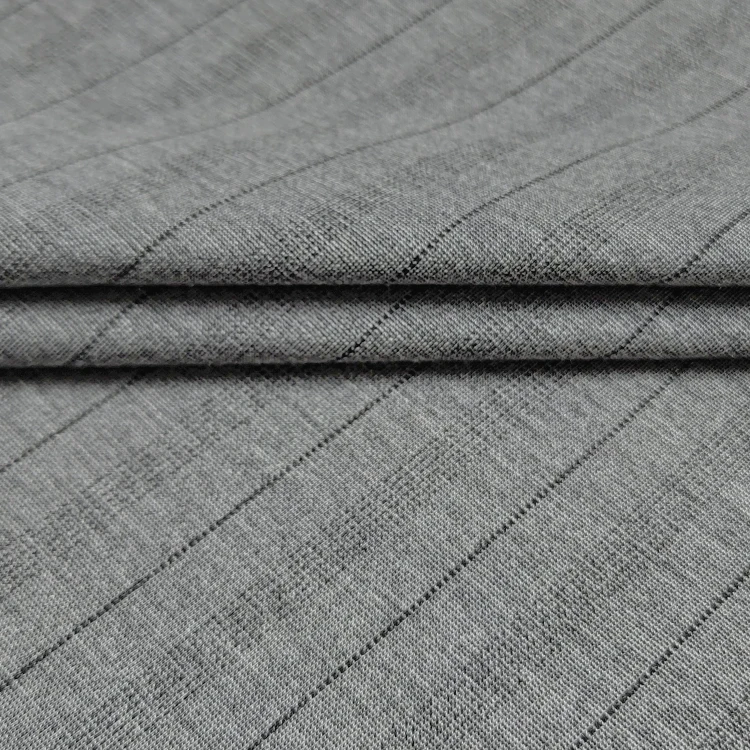

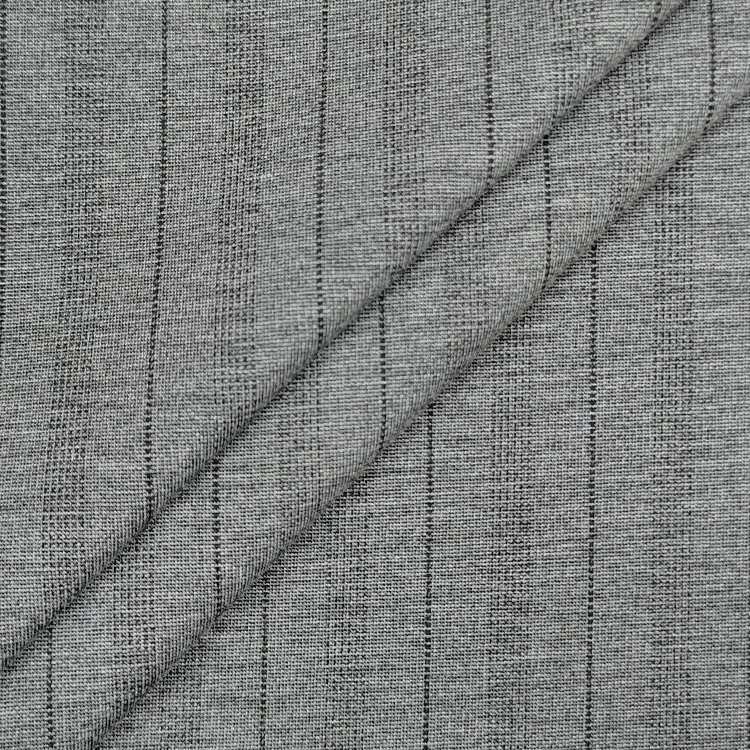

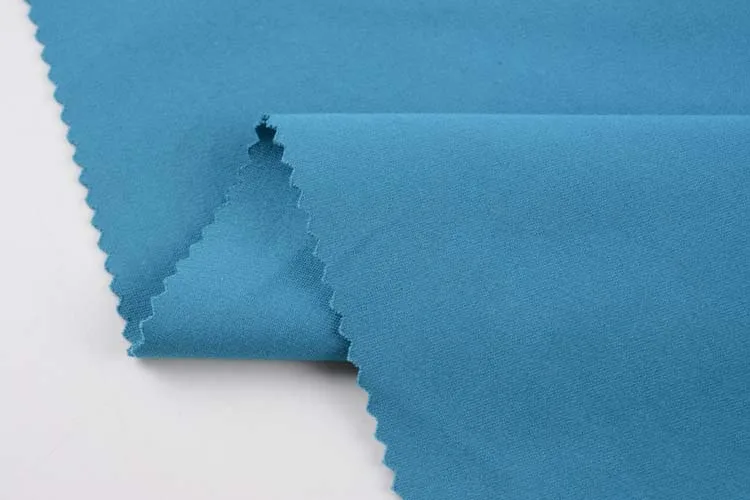

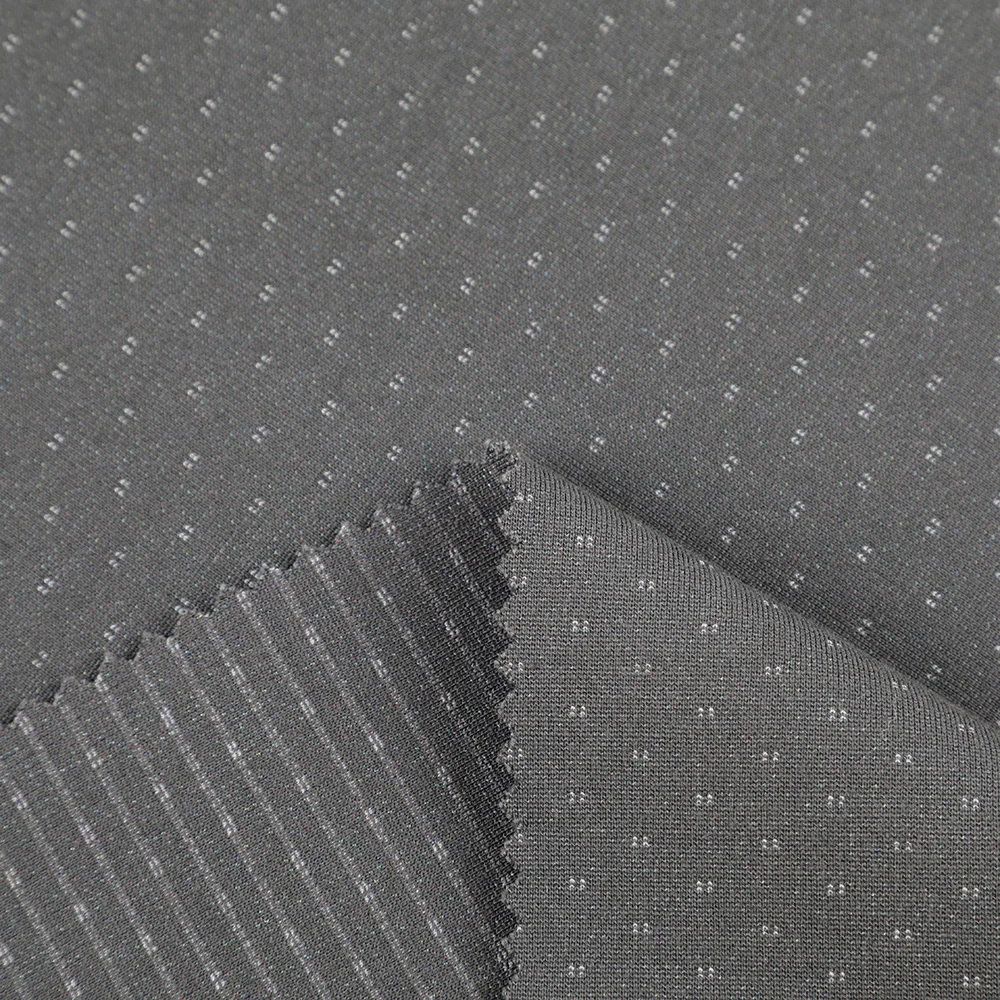

Wholesale Stretch Printed Fabric Nylon Rayon Material Knit Roma Fabric for Women in China

Made in China using advanced knitting technology, this fabric features a medium weight that drapes elegantly and provides comfortable wear throughout the day. The nylon content ensures durability and wrinkle resistance, while the rayon adds a luxurious softness and subtle sheen.

- Overview

- Advantage

- Recommended Products

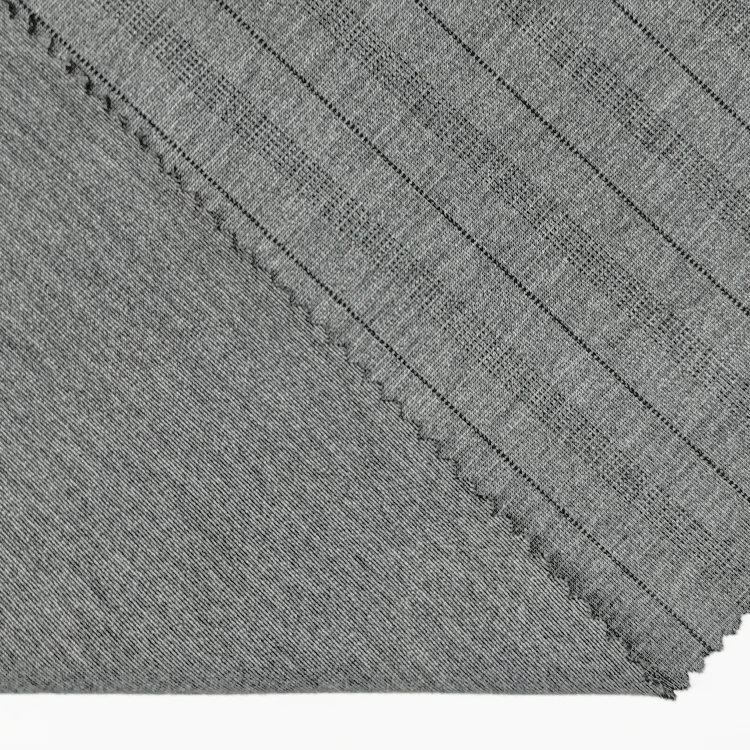

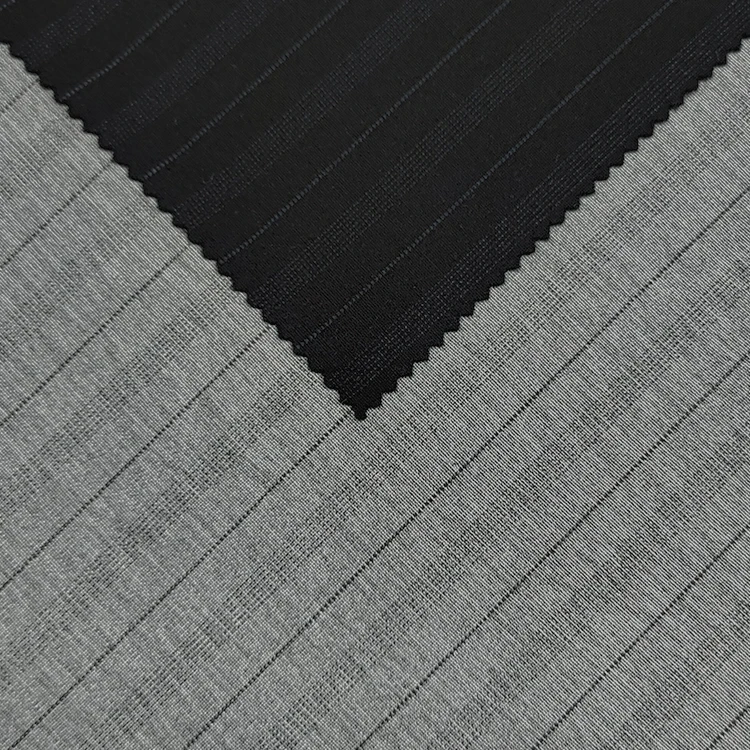

Products Description

Product Name |

NR Ponte Roma PRT |

Product Number |

FM-11281 |

Composition |

70%Rayon 23%Nylon 7%Span |

Width |

61/63" |

Weight |

380GSM |

MOQ |

1000KGS |

Hot Fabric Item Recommend

There are a lot of roma fabrics much inquiried by our customers, such as

40/50/60S Roma, King Roma, NR Roma, RT Roma, TR Roma, NTR Roma...

Feimei is a professional knit fabric factory, free sample can be provided for quality checking.

And we can make according to your order, so INQUIRY us for more detailed info~

FM-12794 40S/50S/60S Roma Fabric

65.4%Rayon 27.2%Nylon 7.4%Spandex, 220gsm, 62/63", OEM available

FM-7492 King Roma Fabric

68%Viscose 28% Nylon 4%Spandex, 380gsm, 60/62", OEM available.

FM-9493 NR Roma Fabric

60%Rayon 35%Nylon 5% Spandex, 320gsm, 62/64", OEM available.

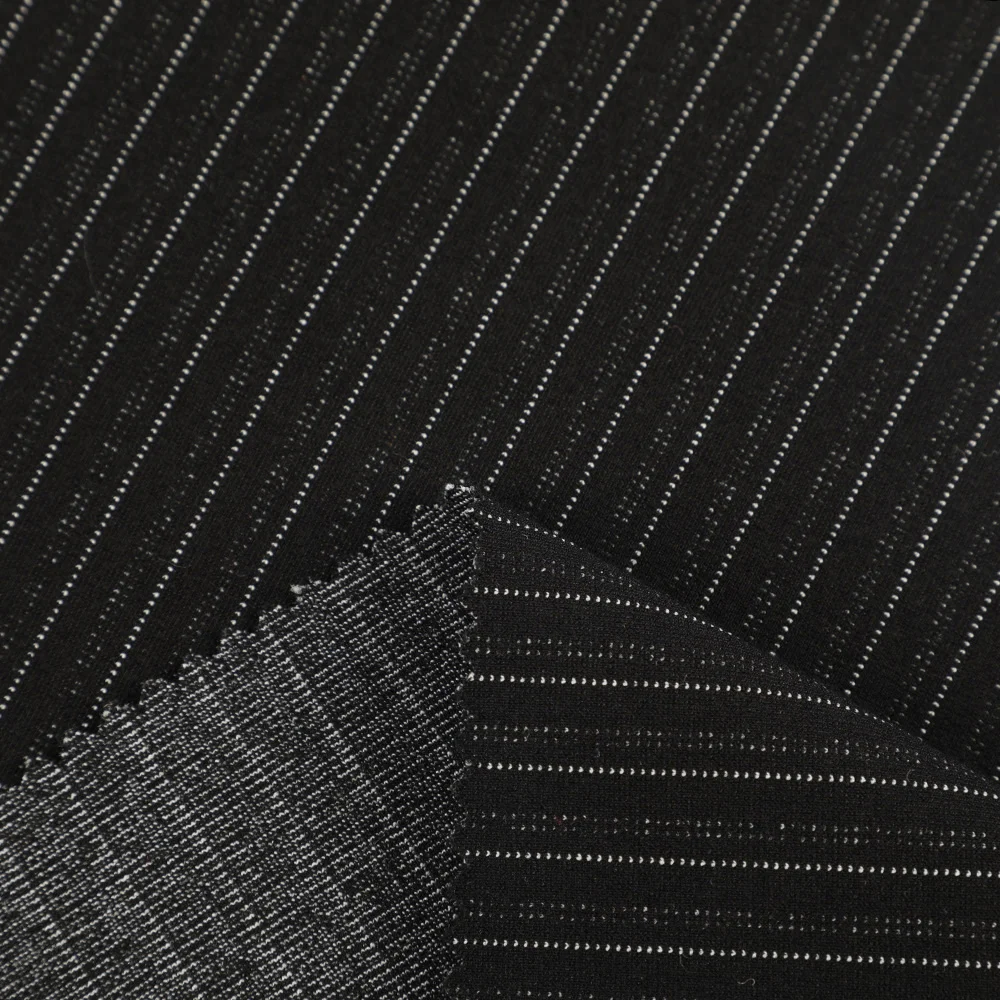

FM-7804 RT Stripe Roma Fabric

70%Rayon 25%Polyetser 5%Spandex, 295gsm, 61/63", OEM available

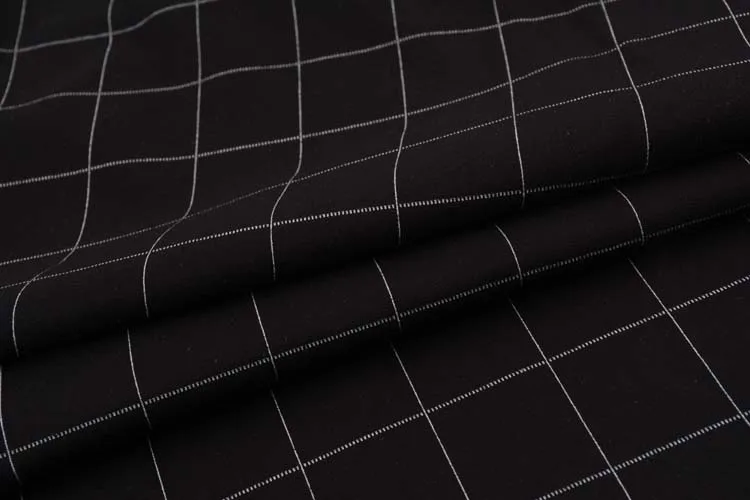

FM-11427 TR Printed Roma Fabric

75%Polyetser 20% Rayon 5%Spandex, 300gsm, 60/62“, OEM available

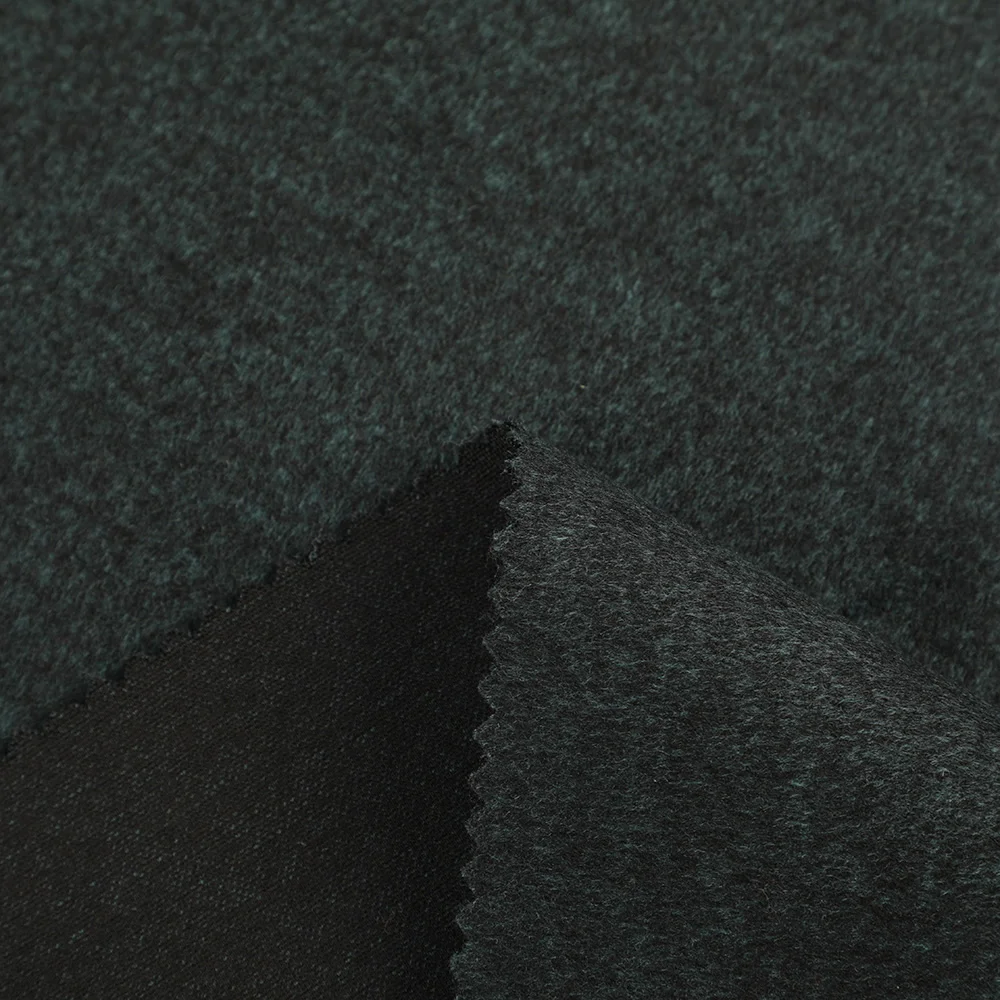

FM-11253 NTR Roma Fabric

60%Ryaon, 20% Nylon, 15% Polyester 5% Spandex, 380gsm, 59/61", OEM available.

FM-10266 Printed Roma Fabric

70%Viscose 25%Nylon 5% Spandex, 390gsm, 62/64", OEM available

What This Fabric Can Be Used For

OEM Available

Not only different colors, but also speical function can be designed according to your order.

Quickly INQUIRY us for more detailed info!

Vortex Roma Fabric

Siro Roma Fabric

Printed Ponti Roma Fabric

Foil Roma Fabric

Light Weight Roma Fabric

Heavy Weight Roma Fabric

Vertical Striped Roma Fabric

Twill Roma Fabric

Roma Jacqaud Fabric

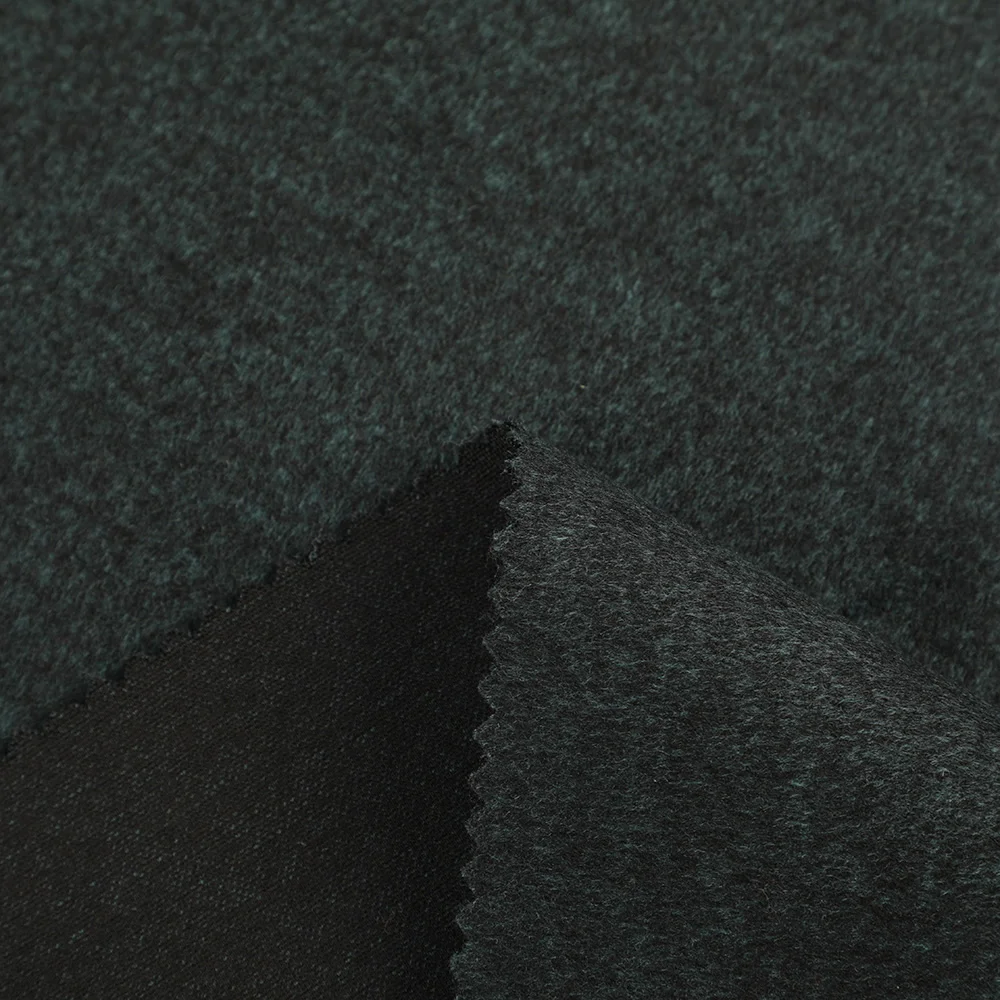

Brushed Roma Fabric

Feimei is Professional knit fabric manufacturer, can make fabrics according to

your requirements. Quickly INQUIRYus and for more detailed info!

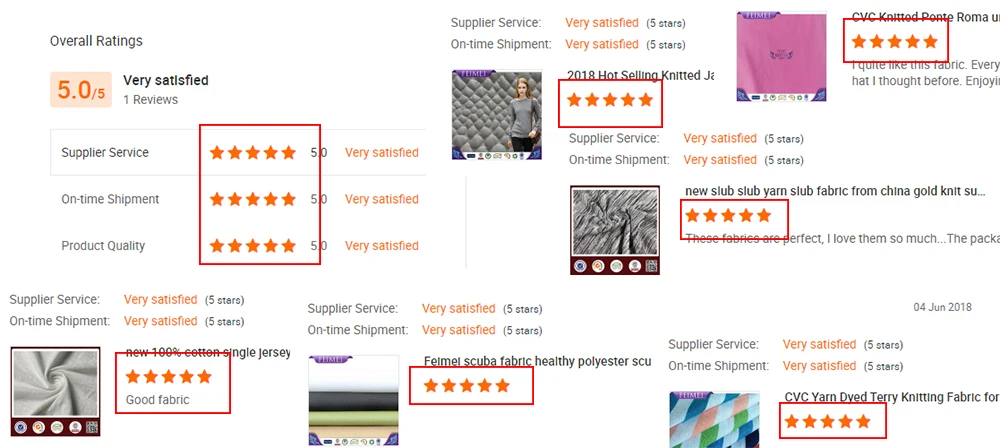

Clients' Review

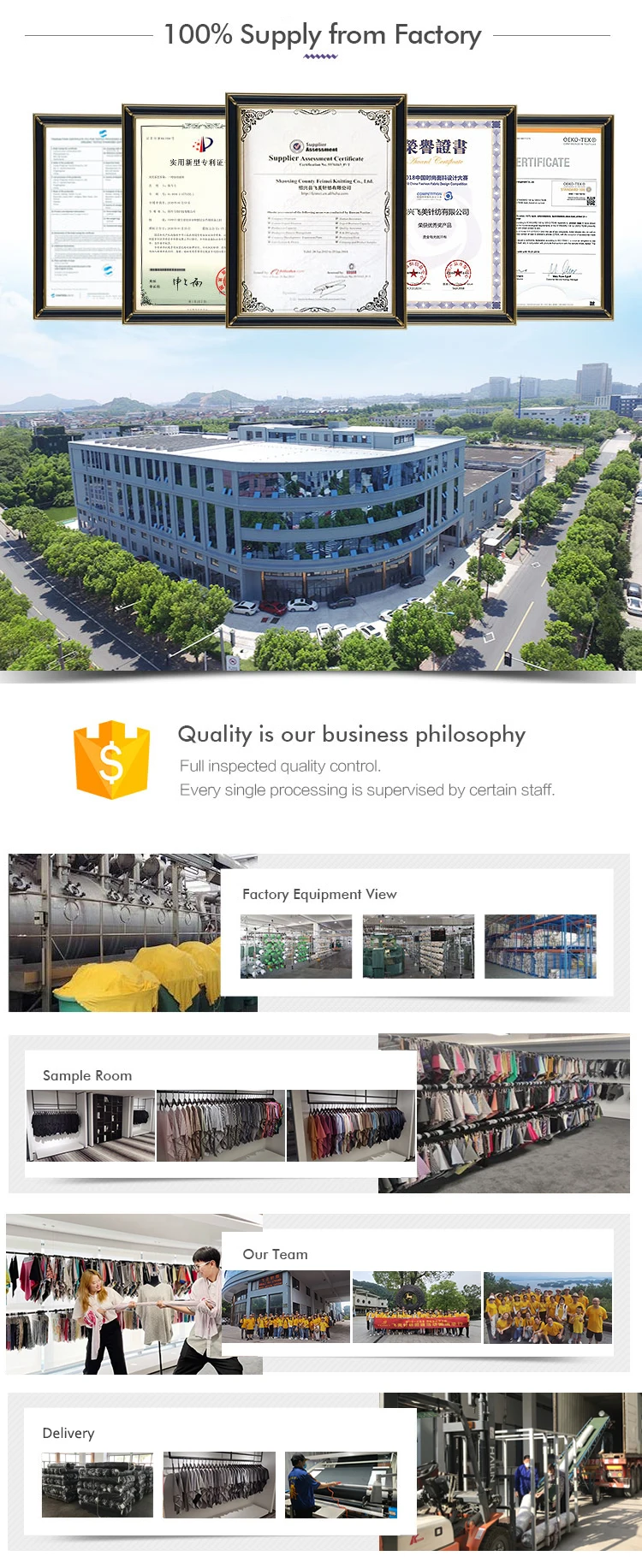

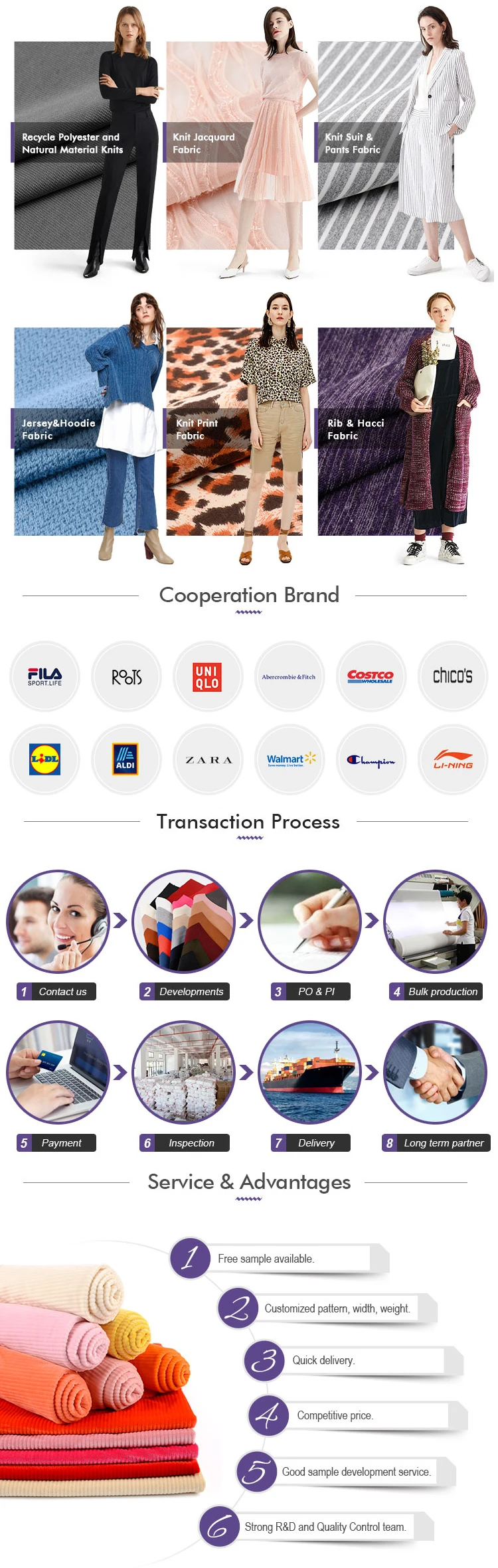

Company Profile

Related Products

FAQ

1.Ordering Information

Payment: we usually accept T/T with 30% deposit, L/C, please send email to negotiate payment term if you can not accept T/T or L/C.

Packing: usually for standard express delivery packing, if quantity more, packaged can be done according to your requirements.

4.How to make an order?

6.More questions?

2.Delivery Time

If ready products, usually will be delivered in 7days. If need to be custom, delivery time can be negotiable. For urgent order, could be faster, please send email to negotiate.

3.Why choose us?

We can do one stop shopping service for our clients with more competitive price and faster delivery, you just need to send us your requirements.

We can do one stop shopping service for our clients with more competitive price and faster delivery, you just need to send us your requirements.

4.How to make an order?

Welcome to try the trade assurance on the Alibaba, which is a good service designed to create trust in trade for protecting your money. And also you can contact us for more TT, LC payment item.

5.How about your shipment?

FedEx, DHL, UPS, other express delivery, sea, airplane, etc. We can advise you the most economical way according to your requirements.

FedEx, DHL, UPS, other express delivery, sea, airplane, etc. We can advise you the most economical way according to your requirements.

6.More questions?

Welcome to contact with us online (24hours).

History and Background

Printed fabric has a long and rich history, dating back centuries when artisans hand-painted or block-printed textiles for clothing, ceremonial attire, and home furnishings. Over time, printing evolved into a highly technical and versatile process, allowing for a wide range of colors, patterns, and textures on different types of fabric. Today, printed fabrics are a cornerstone of fashion and textile design, enabling brands to create visually compelling, customized, and expressive garments that resonate with consumers.

Whether for fashion apparel, casual wear, home textiles, or promotional items, printed fabrics offer a unique combination of functionality and design freedom. The modern market demands not only aesthetic appeal but also durability, comfort, and adaptability, making printed fabrics an essential choice for designers and brands worldwide.

Fiber and Fabric Types

One of the greatest strengths of printed fabrics is their adaptability to a wide variety of fibers and base materials. Our company produces printed fabrics using both woven (plain, twill, satin, and specialty weaves) and knitted fabrics (jersey, interlock, rib, and pique knits). Each type of fabric offers distinct characteristics that affect print clarity, texture, and garment performance:

• Cotton Fabrics: Cotton provides excellent color absorption, soft hand feel, and breathability. Printed cotton fabrics are ideal for casual shirts, dresses, children’s clothing, and home textiles like bedding and curtains. Its natural fibers allow for vivid color reproduction and durable prints that withstand frequent washing.

• Polyester Fabrics: Polyester fabrics, including microfiber, taffeta, and chiffon, offer lightweight strength, high dimensional stability, and vibrant color retention. When printed, polyester maintains sharp patterns with minimal distortion, making it perfect for activewear, promotional garments, and fashion pieces that require bright, long-lasting visuals.

• Blended Fabrics: Combining fibers such as cotton-polyester, cotton-viscose, or bamboo-polyester blends allows the benefits of multiple fibers to be realized. For instance, a cotton-polyester blend printed fabric can provide the softness and comfort of cotton with the structural integrity and durability of polyester. Blended fabrics offer versatility in weight, drape, and texture, making them suitable for diverse apparel categories.

• Specialty Knits and Wovens: Our expertise extends to specialized fabrics such as piqué knits, interlocks, stretch jerseys, satin weaves, and lightweight technical textiles. Each fabric type interacts differently with printing methods, and our team ensures that the selected process enhances both print quality and fabric performance.

This ability to print on both woven and knitted fabrics provides clients with limitless design possibilities, whether the project requires soft drape, stretchability, or structured form.

Printing Techniques and Technical Advantages

Modern printed fabrics benefit from advanced techniques that ensure precision, vibrancy, and durability:

• Rotary Screen Printing: Ideal for large-volume production, rotary screen printing ensures consistent color, accurate pattern registration, and sharp design reproduction. It is highly efficient for repeating patterns on woven and knitted fabrics, particularly in mass production scenarios where cost-effectiveness and consistency are critical.

• Digital Printing: Digital printing allows for unmatched flexibility, including small-batch runs, complex multi-color designs, and photo-realistic images. It is suitable for both woven and knitted fabrics, enabling designers to create highly customized garments with intricate patterns and color gradients. Digital printing also minimizes setup time and reduces material waste, aligning with modern sustainability goals.

• Discharge and Reactive Printing: Depending on fabric composition, we can utilize discharge or reactive printing techniques to achieve different effects, including soft hand feel, bright saturated colors, or vintage washed looks. These methods allow brands to differentiate products with unique textures and visual effects.

Technical advantages of printed fabrics include:

• Color Vibrancy and Stability: Using high-quality, environmentally compliant dyes ensures vivid, long-lasting colors even after repeated washing.

• Pattern Precision: Advanced machinery and quality control ensure accurate registration and consistency across rolls.

• Softness and Comfort: Printing techniques are optimized to maintain the original hand feel and flexibility of the fabric.

• Versatility: From delicate fashion silks to robust uniforms and technical sports fabrics, our printing processes accommodate a wide range of fabric weights, textures, and fiber compositions.

Functional and Market Benefits

Printed fabrics not only offer visual appeal but also bring tangible functional and commercial advantages:

• Fashion and Apparel: Printed fabrics allow for immediate differentiation in competitive fashion markets. Designers can convey brand identity, seasonal themes, and trend-driven aesthetics through patterns, textures, and color combinations. Printed woven fabrics are ideal for dresses, shirts, outerwear, and home décor apparel, while knitted prints suit T-shirts, activewear, loungewear, and children's clothing.

• Customization and Branding: For brands seeking limited editions, seasonal collections, or exclusive designs, digital printing enables highly flexible customization with minimal lead time. The ability to produce small-batch, high-detail prints ensures exclusivity and rapid market responsiveness.

• Functional Performance: Depending on the fiber type, printed fabrics retain key performance features such as stretch, moisture management, breathability, and durability. For example, sportswear prints on polyester knits maintain vibrant colors and flexibility, while cotton prints preserve softness and comfort.

• Market Relevance: Printed fabrics allow brands to respond quickly to trends, offer differentiated products, and expand into niche markets. The combination of design flexibility and production scalability makes printed fabrics a highly valuable component of any fashion or textile strategy.

Company Expertise and Customization Capabilities

Our company has extensive experience producing printed fabrics for both woven and knitted textiles. We have successfully delivered solutions to fashion brands, sportswear manufacturers, and home textile producers worldwide. Key capabilities include:

• Consultation on fabric selection for optimal print quality and garment performance.

• Customization of patterns, color palettes, and print scales to match brand vision.

• Production support for small-batch digital runs and large-scale rotary printing projects.

• Quality assurance protocols, including color matching, wash testing, pattern registration checks, and tactile inspection.

By combining technical know-how with design support, we ensure that each printed fabric meets brand standards while providing creative freedom. Our clients benefit from consistent quality, flexible production, and the ability to bring complex or bespoke designs to market efficiently.

Sustainability and Future Outlook

Sustainability is increasingly central to fabric production. Our printed fabrics utilize eco-friendly dyes and compliant processes, reducing environmental impact while maintaining performance and aesthetics. Digital printing minimizes waste and allows for on-demand production, reducing overstock.

Looking ahead, printed fabrics will continue to evolve with innovative fibers, eco-conscious inks, and hybrid printing technologies. This ensures that brands can offer visually compelling, functional, and environmentally responsible products that meet the expectations of modern consumers.

Our company’s expertise spans both rotary and digital printing, across a wide range of fabrics, with capabilities for customization, quality assurance, and scalable production. We provide solutions that support brand differentiation, design innovation, and market competitiveness. By choosing our printed fabrics, clients gain access to high-quality, flexible, and aesthetically versatile textiles that transform each garment into a unique and compelling expression of creativity.